Why we use in-vehicle testing to validate telematics parameters

To acquire telematics data parameters, a common practice is to use a computerized system to simulate the input and output of the electronic control unit (ECU), also known as bench testing. While this method may be a standard procedure, it leaves room for errors that could have otherwise been detected using in-vehicle testing. At VINVOX, all telematics parameters are verified in-vehicle by our quality assurance experts to ensure that our data is as accurate as possible.

To meet the demand for telematics data, VINVOX has validated over 100,000 parameters for more than 3,000 unique vehicle year, make, and models. As our coverage grows, in-vehicle testing remains an essential part of our process that makes our data reliable and accurate.

We sat down with our Technical Manager, Andy, to dive deeper into the topic of in-vehicle testing at VINVOX.

Why is in-vehicle testing a necessary step that we include in our process?

As automotive technology changes, new parameters need to be identified

As vehicle technology continues to change, parameters may be added or changed to accommodate for new functions. For example, the gear shift mechanism has evolved significantly over the years, from the original lever to buttons and knobs in many vehicles today. While these adjustments may have improved the driving experience, they have created a new set of challenges for telematics service providers.

VINVOX has invested heavily into our in-vehicle testing process to maintain our coverage of over 3,000 different vehicle year make and models. Parameters need to be revalidated with every new model year to account for new functionality and changes to the vehicle. At times, the parameters can even change when there are no physical changes to the vehicle’s features, making the in-vehicle validation of parameters a crucial step in ensuring the data is as accurate as possible.

Mandated parameters have specified locations that are not always used

Mandated parameters are not always found at their specified address, making them challenging to locate. We have dedicated well over a decade to R&D efforts to find these alternate addresses. This variation in locations can occur due to legacy implementations and changes in automotive technology like with the gear shift mechanism. Our process of validating the parameters in-vehicle ensures that the parameters we support truly reflect what our clients have in their fleet.

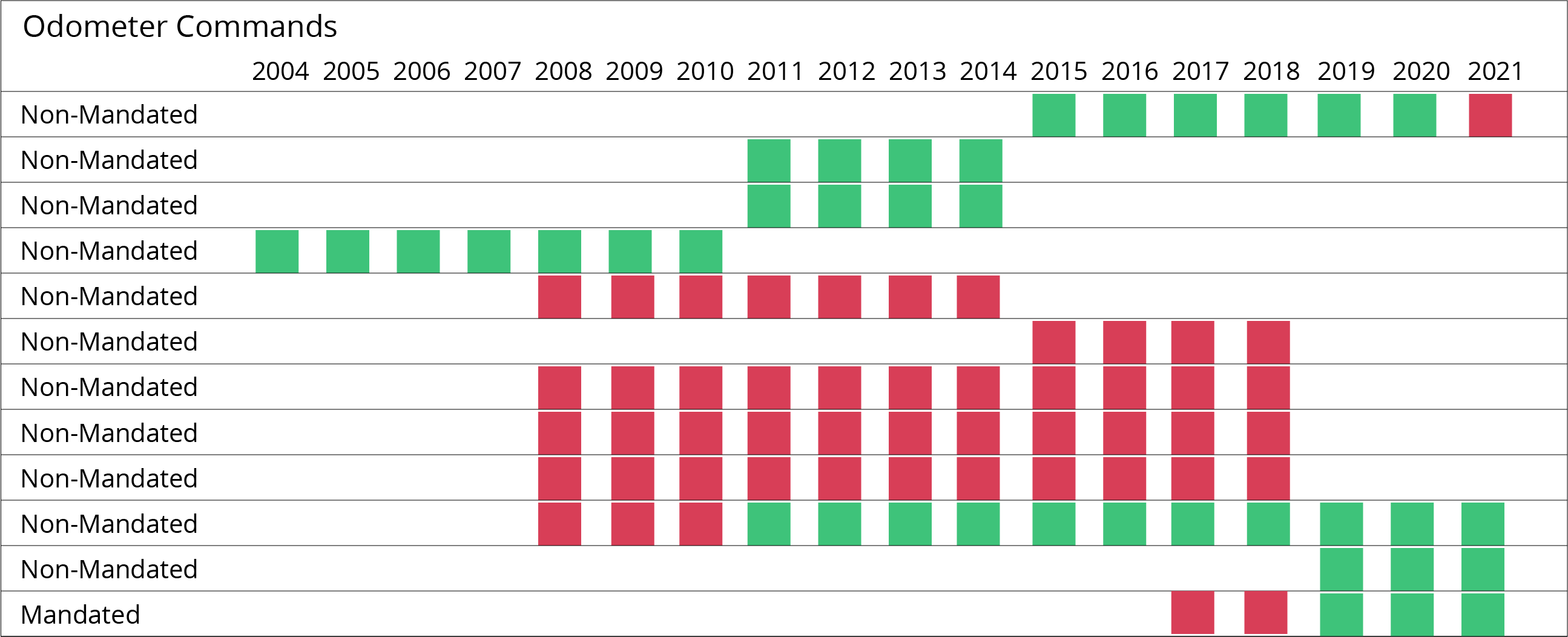

In certain vehicles, there are a number of locations from which you can retrieve the odometer value within the vehicle’s network, and these can change from year to year. We have identified that some sources for odometer data can be more reliable and with higher precision than others.

In the example below, the green squares represent the different commands that VINVOX uses to retrieve the odometer data of a particular vehicle in each new year model. In 2021 for example, a parameter that may have been supported in previous years can no longer be supported. In other cases, a command that previously was not supported may become available in a new year like in 2011.

Note that the mandated location does not necessarily guarantee reliable results. At times, locating alternate addresses is necessary to support accurate data.

Using in-vehicle testing allows us to validate the parameters against the vehicle dashboard, providing additional data to confirm the accuracy of our results.

Baud rates can impact the way a vehicle reacts to testing and research

Baud rate is the speed at which data is communicated over a vehicle’s communication channel, for example, the controller area network (CAN) bus or the K-Line.

The speed at which the data is communicated must match what the vehicle is expecting. For example, generally, MSCAN (medium speed controller area network) communicates at 125 kbit/s and 500 kbit/s BAUD, while up to 1 Mbit/s is possible. However, OEMs can change baud rates year over year, which can impact data reliability.

Using a baud rate that is incompatible with a vehicle can cause unpredictable behaviour that may only be exposed when performing in-vehicle testing. By validating the parameters in-vehicle, we are able to identify issues like a mismatched baud rate to ensure that our data is as reliable as possible.

What is our process for gathering and validating parameters?

- Our engineers perform bench tests in preparation for in-vehicle testing. PIDs are captured by simulating a vehicle to analyze how information is stored in the vehicle’s computer.

- In-vehicle testing is carried out by our engineers to validate the data. Adjustments are then made to the simulated data to ensure its accuracy.

- The data is uploaded to our servers for quality assurance testing, at which point the data is revalidated.

- Our quality assurance team conducts in-vehicle testing using our proprietary testing application. This verifies the quality of the data and confirms any additional changes performed by the engineer.

- The engineer does a final validation of the results using our proprietary tools.

- The data is then made available to our customers through the Fetch application programming interface (API).

What happens if we do not perform in-vehicle testing?

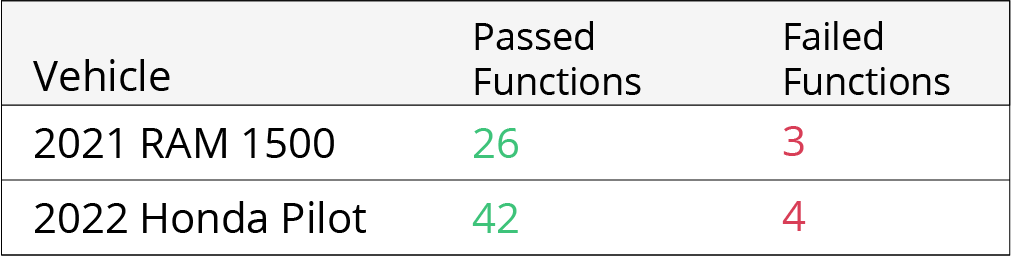

In the table of recent scans below, you can see that some of the commands we tested needed further refinement from our engineers to improve the results. This would not have been exposed without our in-vehicle testing. In-vehicle testing is a crucial step in our process that contributes to the level of accuracy in the telematics data we provide to our customers.

Final Thoughts

We make in-vehicle testing a priority process at VINVOX to ensure our clients work with the most accurate telematics data available.

Without in-vehicle testing, parameter changes could be missed as vehicles change, leading to inaccurate data for clients like fleet managers to work with. Mismatched baud rates can lead to equally unreliable data, that may not be identified without in-vehicle testing. Finally, mandated parameters don’t always appear in their specified locations, which can drastically increase R&D costs for those building telematics-based solutions.

We make in-vehicle testing a top priority at VINVOX so that our clients know that the telematics data they work with will be accurate and reliable.

To learn more about in-vehicle testing and our coverage, get in touch!